Custom rigid boxes are premium packaging solutions made from thick paperboard for superior strength and luxury presentation. They offer excellent protection, high-end finishes, and full customization for upscale products.

Get Free Quote

We have an extensive range of custom packaging. Browse to find your custom packaging solution

View More ProductsCustom rigid boxes are high-quality packaging boxes constructed from dense, non-collapsible paperboard. Unlike folding cartons, rigid boxes maintain their shape and structure, giving products a solid, premium feel from the first touch.

They are widely used for luxury packaging where durability and presentation are essential.

Rigid boxes are designed to deliver strength and sophistication. Key benefits include:

Thick, sturdy construction for maximum protection

Fixed shape that enhances perceived product value

Clean edges and precise structure

Suitable for premium closures and inserts

These features make rigid boxes ideal for high-value items.

Custom rigid boxes are manufactured using top-grade materials, including:

Rigid greyboard or chipboard for durability

Premium art paper wraps for refined finishes

Eco-friendly and recyclable paper-based materials

Custom inner linings for added protection

Material selection depends on product weight and branding requirements.

Rigid boxes offer extensive customization to elevate brand identity. Available options include:

Custom sizes and box styles

Matte, gloss, or soft-touch lamination

Foil stamping, embossing, debossing, and spot UV

Magnetic closures, ribbon pulls, or lift-off lids

Custom inserts and compartments

These boxes are commonly used for:

Luxury retail and fashion products

Cosmetics and skincare packaging

Electronics and tech accessories

Jewelry, watches, and gift items

Corporate and promotional packaging

Their premium structure enhances presentation and protection.

Custom rigid boxes help brands communicate quality, exclusivity, and trust. They protect valuable products while delivering a memorable unboxing experience.

If you want packaging that feels luxurious, durable, and brand-driven, custom rigid boxes are the perfect choice.

Choose a packaging style for your custom boxes, start designing with us, and get your boxes with the most advanced printing techniques.

Materials

Materials

Coating Options

Coating Options

Printing Methods

Printing Methods

Color Options

Color Options

AddOns

AddOns

SBS C1S

SBS C1S

Premium-grade bleached white paperboard with one-sided coating for high-quality color printing and finishes.

SBS C2S

SBS C2S

Premium-grade white art card coated on both sides for high-quality printing and finishing options.

Kraft Card

Kraft Card

Brown Kraft Card is made of virgin and recycled pulp and coated on both sides for printing.

Textured Card

Textured Card

Textured paper stock is primarily used to wrap rigid boxes and is of the highest grade.

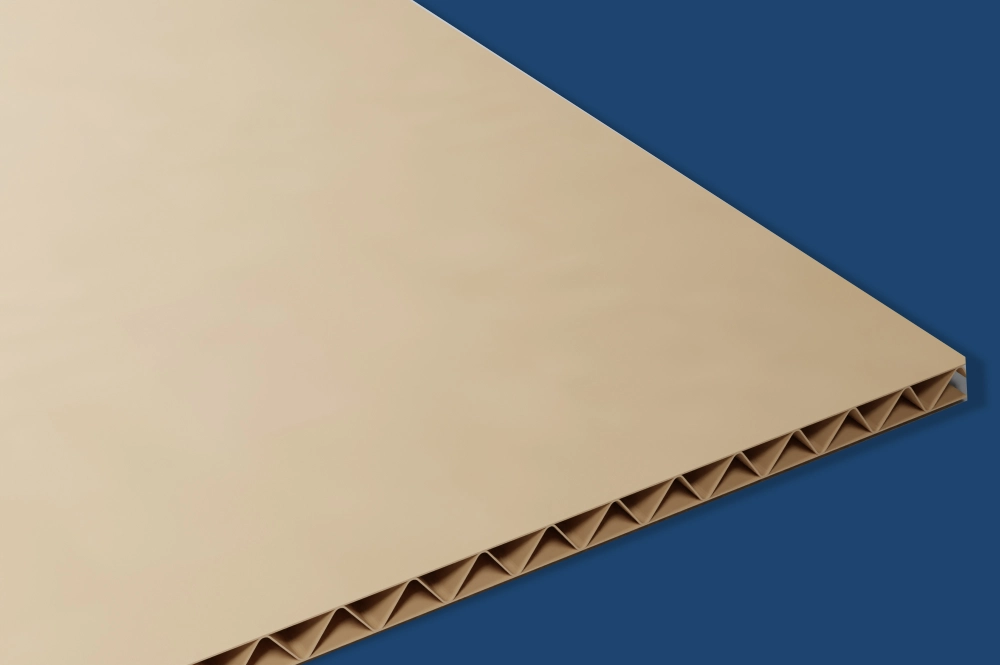

Brown flute

Brown flute

An uncoated and unbleached linerboard composed of recycled and virgin paper pulp.

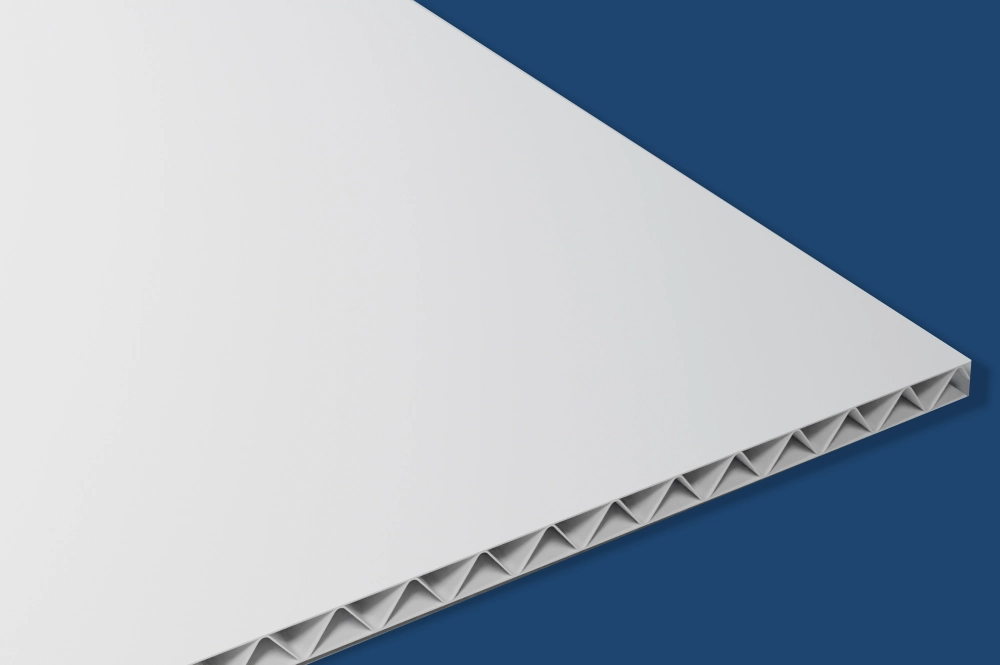

White flute

White flute

White linerboard with bleached white coating for high-quality printing and finishes.

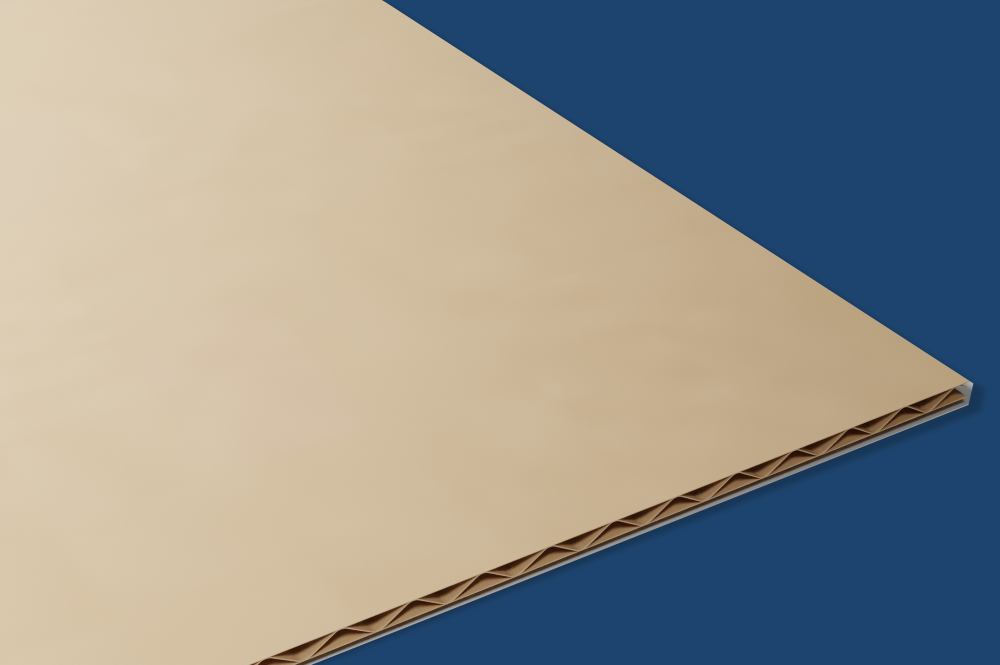

E-flute

E-flute

A flat surface with a thickness level of 1/16" allows high-quality printing options.

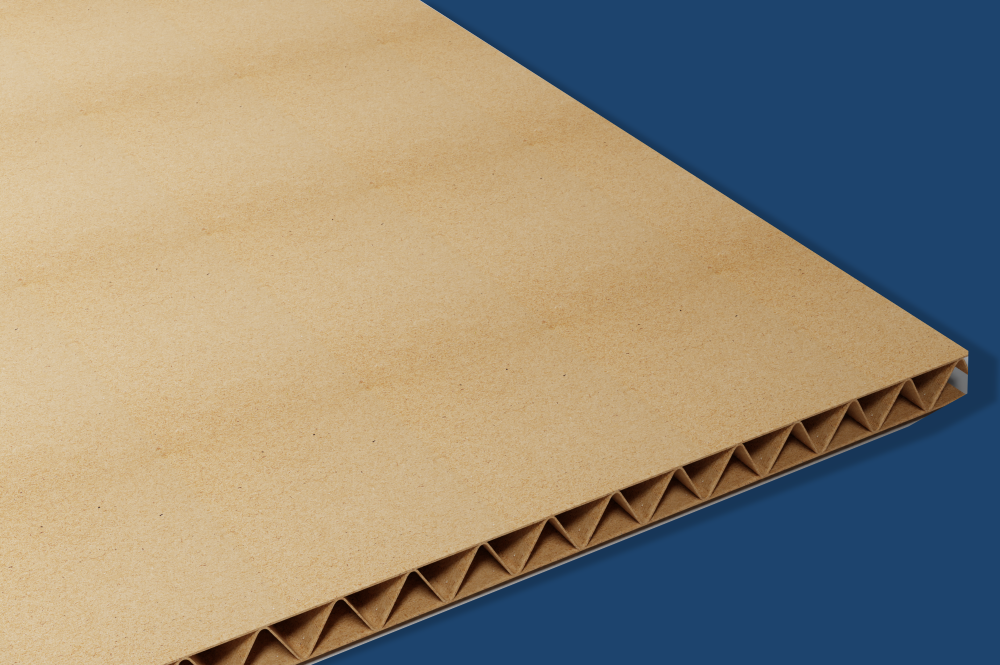

B-flute

B-flute

A slightly thicker surface with a thickness level of 1/8" for die-cutting and high-quality printing.

Grey Chipboard

Grey Chipboard

Grey Chipboard made of recyclable paper pulp, which is used in the construction of rigid boxes.

Duplex Chipboard

Duplex Chipboard

Duplex Chipboard made of recycled pulp paper with a white surface for high-quality printing.

Kraft Chipboard

Kraft Chipboard

Brown Kraft Chipboard is made of virgin and recycled pulp and coated on both sides for printing.

Aqueous

Aqueous

Water-based coating offers environmental friendliness and fast drying.

Gloss

Gloss

A highly reflective coating gives a shiny, polished appearance.

Matte

Matte

Diffused, non-reflective coating offering a subdued, elegant look.

Soft Touch

Soft Touch

This creates a velvety, tactile feel, often used for a luxurious effect.

UV Coating

UV Coating

Cured with ultraviolet light, provides instant drying, durable, and excellent chemical resistance.

Varnish

Varnish

Clear, hard coating that enhances protection and adds a glossy or matte finish.

Digital Print

Digital Print

A plate-less digital printing method where designs are transferred electronically. Cost-effective for short runs and quick turnaround.

Offset Print

Offset Print

High-quality printing method utilizing plates and a rubber blanket to transfer designs onto paper; ideal for large-volume production.

Screen Print

Screen Print

A printing method where ink is pushed through a mesh stencil onto a substrate. Ideal for bold graphics and thick ink deposits on diverse materials.

UV Print

UV Print

Fast-drying printing method using ultraviolet light to cure inks, resulting in a durable, glossy finish on various substrates.

CMYK

CMYK

A standard four-color printing process (Cyan, Magenta, Yellow, Black) is used to create a wide color spectrum.

Pantone

Pantone

A standardized color-matching system ensures accurate color reproduction across different printers and materials.

UV Ink

UV Ink

Instantly cured under UV light, it is ideal for printing on non-porous materials, with enhanced durability and vibrancy (can include metallic effects).

Soy Ink

Soy Ink

Eco-friendly ink alternative made from soybeans, offering brighter colors and improved biodegradability.

Blind UV

Blind UV

Creates a subtle, textured UV effect without added gloss.

Debossing

Debossing

Creates a depressed, indented effect on paper or cardstock.

Embossing

Embossing

Creates a raised, textured effect on paper or cardstock.

Foiling

Foiling

Adds a shiny, metallic finish to specific areas of a design.

Spot UV

Spot UV

Applies a glossy, clear coating to highlight specific areas of a design.

Window Patching

Window Patching

Incorporates a clear plastic window into packaging or print materials.

We believe custom packaging should be exceptional that’s why we’re passionate about creating boxes that leave a lasting impression. Our commitment to quality and customer satisfaction has earned us a loyal following. See for yourself:

“I was looking for a cosmetic box for lip gloss and i did not know which style to choose for my box. Refine Custom Boxes's agent Victor helped me to choose a reverse tuck end that was perfect for my product.”

“Overall a very positive experience! My boxes came out perfectly and the customer service was simply excellent.”

“My order was rushed, and they cooperated with me throughout the process, completing it within the given time. Excellent printing and material quality.”

If you don’t find what you are looking for, feel free to contact us via email and we will be happy to assist.

Rigid gift boxes are sturdy, uniform-sized containers used for safely transporting gifts and fragile items. Their flat shape simplifies storage and selection. And they offer customization options such as printed paper or stickers. With strong walls, they ensure items remain undamaged during transport, providing peace of mind to both sender and recipient.

Yes. Rigid boxes are well-suited for products when they custom inserts to give products a perfect fit. Let our experts know if you require a custom insert for your rigid box packaging.

The pricing of your box printing depends on multiple factors. Those factors may include the selection of material, its thickness level, finishing, and add-ons. Please fill in a quote form to get your instant quotation ready.

Yes. You have the option to ask for a 3D mock/2D proof for your artwork. Our design experts will send the 2D proof through mail. Upon your approval, we will proceed with the printing process.

Yes. You can request a 3D mockup or 2D proof of your box from our design support team. Once you approve the digital proof, we will start the manufacturing process.

Looking to place a rush order? Get Your Order Shipped Fast! We accept rush orders on all of our products. Please fill out the form below and our chat support will contact you shortly.