Burger boxes are food-grade packaging solutions designed to keep burgers fresh, warm, and secure during serving and delivery. They offer grease resistance, sturdy structure, and customizable branding for food businesses.

Burger boxes are specially designed food packaging boxes used to serve and transport burgers safely. These boxes are crafted to maintain the shape, temperature, and freshness of burgers while preventing grease leakage and sogginess.

They are widely used by restaurants, food trucks, cafes, and takeaway brands for both dine-in and delivery services.

Burger boxes are designed to meet the practical demands of food packaging. Key benefits include:

Grease-resistant coating to prevent oil leakage

Ventilation options to reduce moisture buildup

Secure closure to keep burgers intact

Sturdy structure for stacking and transport

These features help ensure burgers reach customers in perfect condition.

Burger boxes are manufactured using food-safe and durable materials, including:

Kraft paperboard for eco-friendly packaging

SBS paperboard for clean and premium presentation

Corrugated board for delivery and takeaway orders

Recyclable and biodegradable material options

All materials are suitable for direct food contact and comply with food safety standards.

Burger boxes can be customized to reflect brand identity and enhance customer experience. Custom options include:

Full-color food-safe printing

Matte or gloss coatings

Custom box sizes for single or double burgers

Logo placement and brand messaging

Die-cut vents or custom locking styles

These boxes are commonly used for:

Fast food and quick-service restaurants

Food trucks and street food vendors

Cafes and casual dining brands

Takeout and delivery packaging

Promotional and branded food packaging

Their practical design makes them essential for modern food businesses.

Custom burger boxes help food brands deliver quality, consistency, and brand recognition. They improve food presentation, protect product freshness, and create a memorable customer experience.

If you want reliable, hygienic, and visually appealing packaging, burger boxes are an ideal choice.

Choose a packaging style for your custom boxes, start designing with us, and get your boxes with the most advanced printing techniques.

Materials

Materials

Coating Options

Coating Options

Printing Methods

Printing Methods

Color Options

Color Options

AddOns

AddOns

SBS C1S

SBS C1S

Premium-grade bleached white paperboard with one-sided coating for high-quality color printing and finishes.

SBS C2S

SBS C2S

Premium-grade white art card coated on both sides for high-quality printing and finishing options.

Kraft Card

Kraft Card

Brown Kraft Card is made of virgin and recycled pulp and coated on both sides for printing.

Textured Card

Textured Card

Textured paper stock is primarily used to wrap rigid boxes and is of the highest grade.

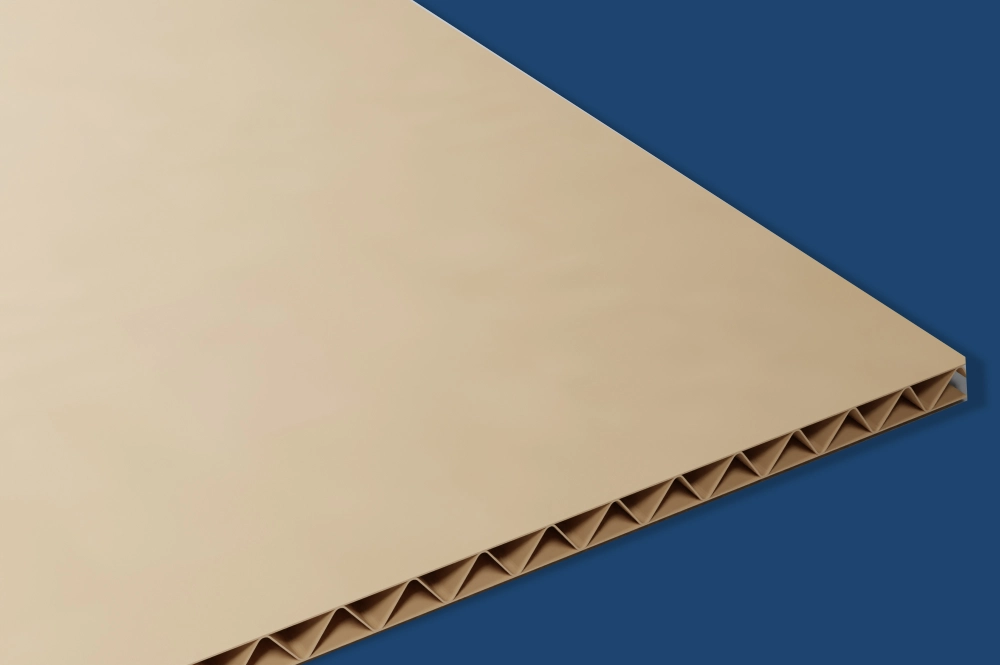

Brown flute

Brown flute

An uncoated and unbleached linerboard composed of recycled and virgin paper pulp.

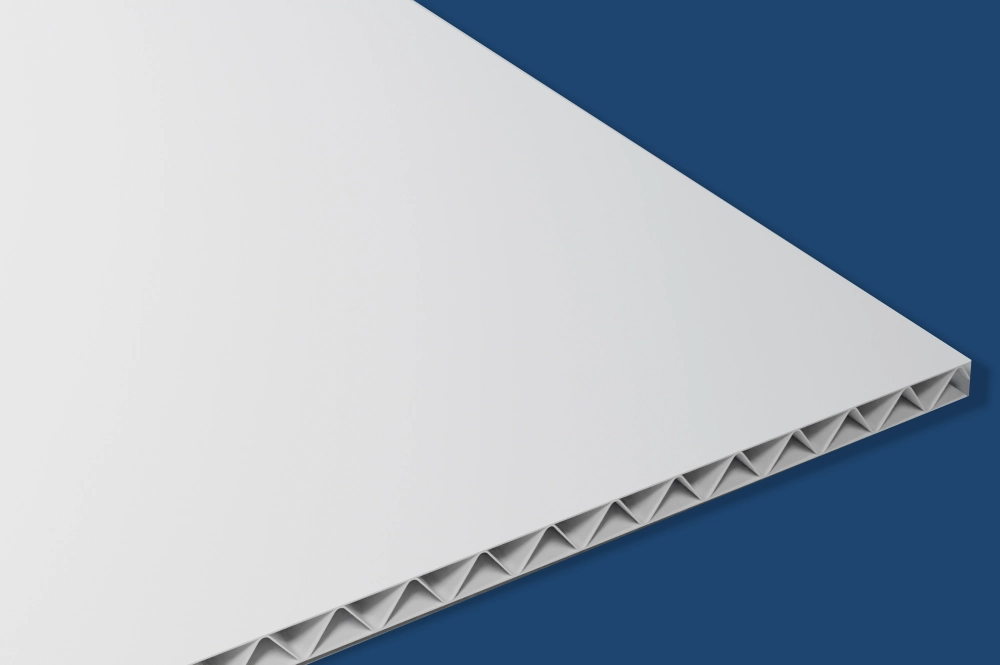

White flute

White flute

White linerboard with bleached white coating for high-quality printing and finishes.

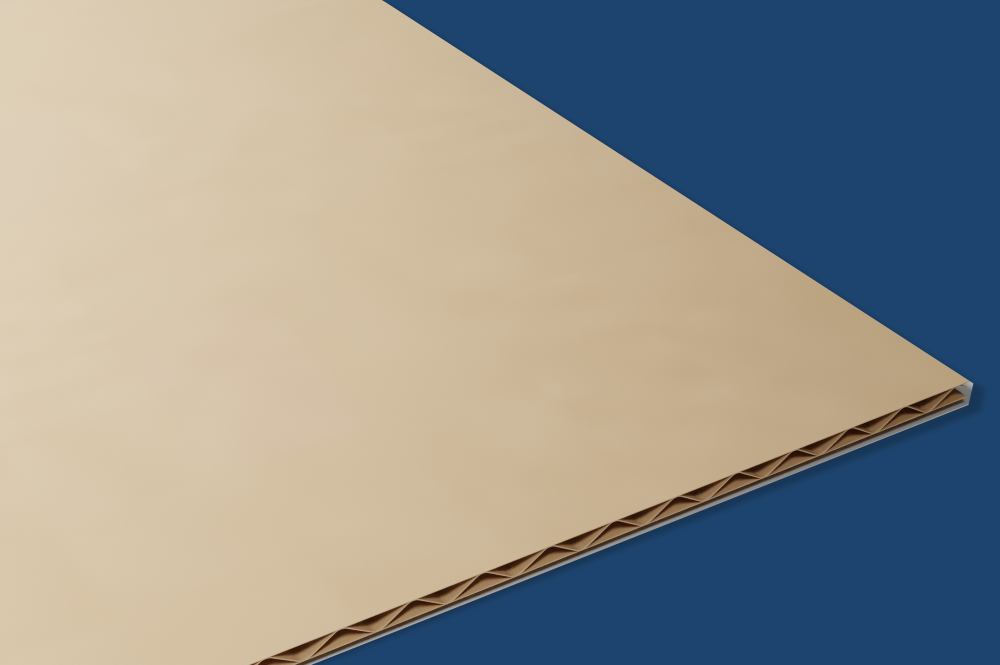

E-flute

E-flute

A flat surface with a thickness level of 1/16" allows high-quality printing options.

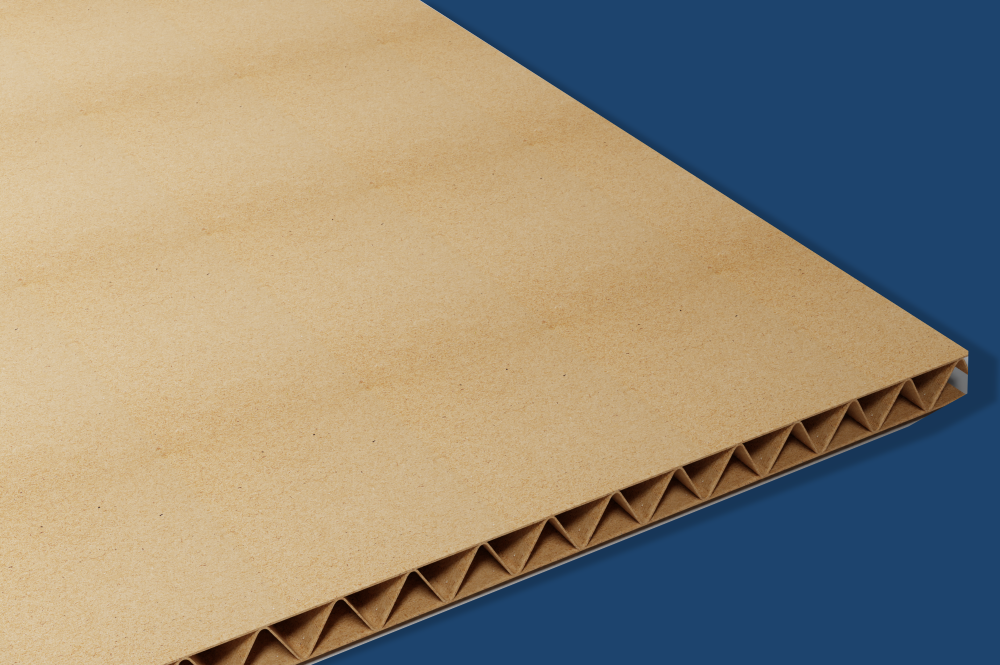

B-flute

B-flute

A slightly thicker surface with a thickness level of 1/8" for die-cutting and high-quality printing.

Grey Chipboard

Grey Chipboard

Grey Chipboard made of recyclable paper pulp, which is used in the construction of rigid boxes.

Duplex Chipboard

Duplex Chipboard

Duplex Chipboard made of recycled pulp paper with a white surface for high-quality printing.

Kraft Chipboard

Kraft Chipboard

Brown Kraft Chipboard is made of virgin and recycled pulp and coated on both sides for printing.

Aqueous

Aqueous

Water-based coating offers environmental friendliness and fast drying.

Gloss

Gloss

A highly reflective coating gives a shiny, polished appearance.

Matte

Matte

Diffused, non-reflective coating offering a subdued, elegant look.

Soft Touch

Soft Touch

This creates a velvety, tactile feel, often used for a luxurious effect.

UV Coating

UV Coating

Cured with ultraviolet light, provides instant drying, durable, and excellent chemical resistance.

Varnish

Varnish

Clear, hard coating that enhances protection and adds a glossy or matte finish.

Digital Print

Digital Print

A plate-less digital printing method where designs are transferred electronically. Cost-effective for short runs and quick turnaround.

Offset Print

Offset Print

High-quality printing method utilizing plates and a rubber blanket to transfer designs onto paper; ideal for large-volume production.

Screen Print

Screen Print

A printing method where ink is pushed through a mesh stencil onto a substrate. Ideal for bold graphics and thick ink deposits on diverse materials.

UV Print

UV Print

Fast-drying printing method using ultraviolet light to cure inks, resulting in a durable, glossy finish on various substrates.

CMYK

CMYK

A standard four-color printing process (Cyan, Magenta, Yellow, Black) is used to create a wide color spectrum.

Pantone

Pantone

A standardized color-matching system ensures accurate color reproduction across different printers and materials.

UV Ink

UV Ink

Instantly cured under UV light, it is ideal for printing on non-porous materials, with enhanced durability and vibrancy (can include metallic effects).

Soy Ink

Soy Ink

Eco-friendly ink alternative made from soybeans, offering brighter colors and improved biodegradability.

Blind UV

Blind UV

Creates a subtle, textured UV effect without added gloss.

Debossing

Debossing

Creates a depressed, indented effect on paper or cardstock.

Embossing

Embossing

Creates a raised, textured effect on paper or cardstock.

Foiling

Foiling

Adds a shiny, metallic finish to specific areas of a design.

Spot UV

Spot UV

Applies a glossy, clear coating to highlight specific areas of a design.

Window Patching

Window Patching

Incorporates a clear plastic window into packaging or print materials.

To order custom boxes, fill out the quotation form. Let us know the material and finishing options you'd like for your boxes.

Our design team will review your submitted artwork. If any changes are needed, they'll let you know and guide you on file formats and resolution.

Several factors can affect the pricing of your custom boxes, including the material you choose, add-ons, finishing options, and color printing.

Yes, absolutely! Mailer boxes are made of corrugated cardboard and come in two different thicknesses (E-flute 1/16" and B-flute 1/8") to suit your product type. Both options are perfect for shipping.

Yes. You can request a 3D mockup or 2D proof of your box from our design support team. Once you approve the digital proof, we will start the manufacturing process.

Choose a packaging style for your custom boxes, start designing with us, and get your boxes with the most advanced printing techniques.

Looking to place a rush order? Get Your Order Shipped Fast! We accept rush orders on all of our products. Please fill out the form below and our chat support will contact you shortly.