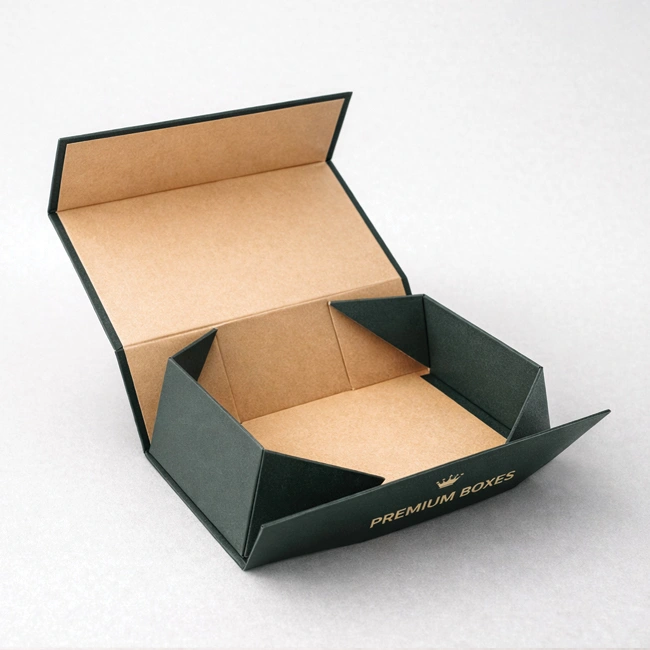

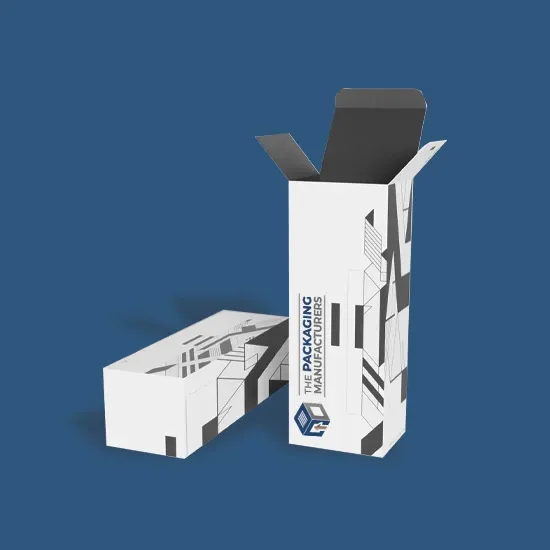

Folding carton boxes are lightweight, versatile packaging solutions designed for retail and consumer products. They offer cost-effective production, easy assembly, and excellent branding space across multiple industries.

Folding carton boxes are paperboard packaging boxes that are delivered flat and folded into shape during filling. They are one of the most commonly used packaging types for retail products due to their flexibility, affordability, and compatibility with high-quality printing.

These boxes are ideal for products that require protection while maintaining a clean and professional appearance.

Folding cartons are engineered for efficiency and presentation. Key benefits include:

Flat shipping for reduced storage and transport costs

Easy assembly by hand or machine

Lightweight yet sturdy construction

Smooth panels for high-impact branding

Their structure supports both practicality and visual appeal.

Folding carton boxes can be manufactured using a variety of paperboard materials, including:

SBS paperboard for premium retail packaging

Kraft paperboard for eco-friendly options

Coated cardstock for vibrant printing

Recyclable and sustainable material options

Material choice depends on product weight, shelf life, and branding needs.

Folding cartons offer extensive customization to meet branding and product requirements. Available options include:

CMYK and Pantone color printing

Matte, gloss, or aqueous coatings

Embossing, debossing, and foil stamping

Custom box styles, sizes, and closures

Window cutouts and inside printing

These boxes are widely used for:

Food and beverage packaging

Cosmetics and personal care products

Pharmaceutical and healthcare items

Electronics and accessories

Retail and promotional products

Their adaptability makes them suitable for mass-market and premium products alike.

Folding carton boxes provide an efficient and reliable packaging solution that balances cost, protection, and branding. They are easy to customize, environmentally friendly, and ideal for high-volume production.

If you want packaging that delivers flexibility and visual impact, folding carton boxes are an excellent choice.

Choose a packaging style for your custom boxes, start designing with us, and get your boxes with the most advanced printing techniques.

Materials

Materials

Coating Options

Coating Options

Printing Methods

Printing Methods

Color Options

Color Options

AddOns

AddOns

SBS C1S

SBS C1S

Premium-grade bleached white paperboard with one-sided coating for high-quality color printing and finishes.

SBS C2S

SBS C2S

Premium-grade white art card coated on both sides for high-quality printing and finishing options.

Kraft Card

Kraft Card

Brown Kraft Card is made of virgin and recycled pulp and coated on both sides for printing.

Textured Card

Textured Card

Textured paper stock is primarily used to wrap rigid boxes and is of the highest grade.

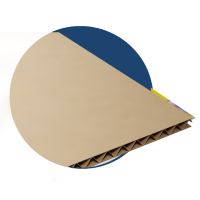

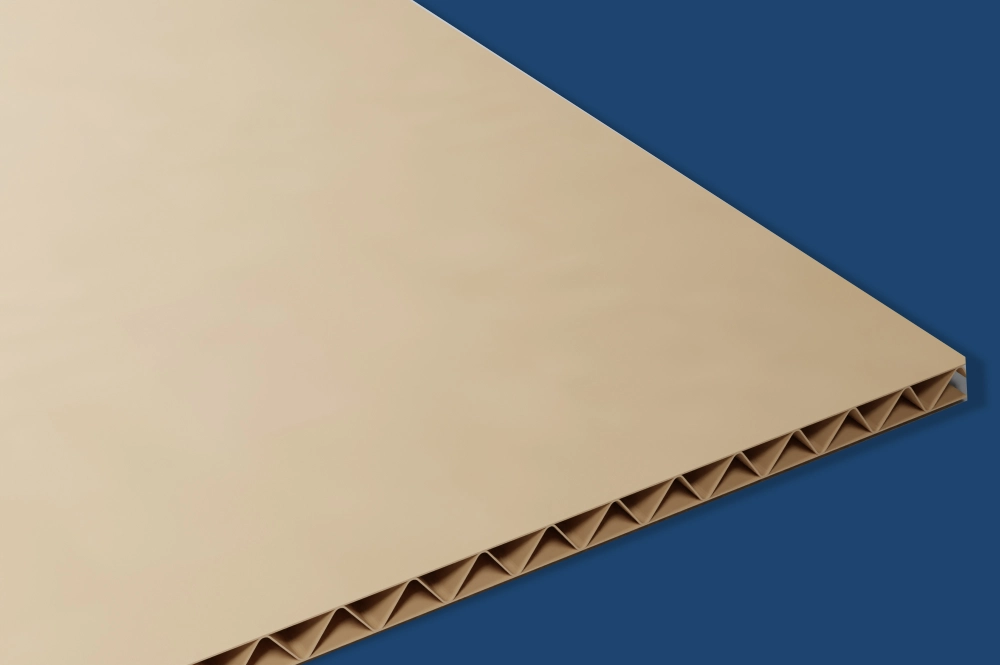

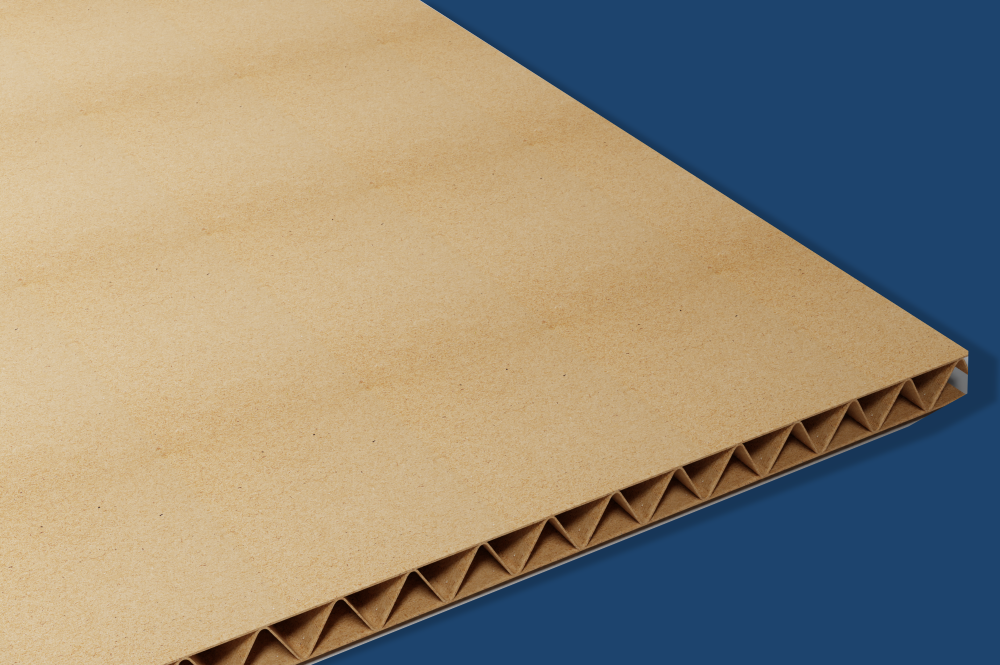

Brown flute

Brown flute

An uncoated and unbleached linerboard composed of recycled and virgin paper pulp.

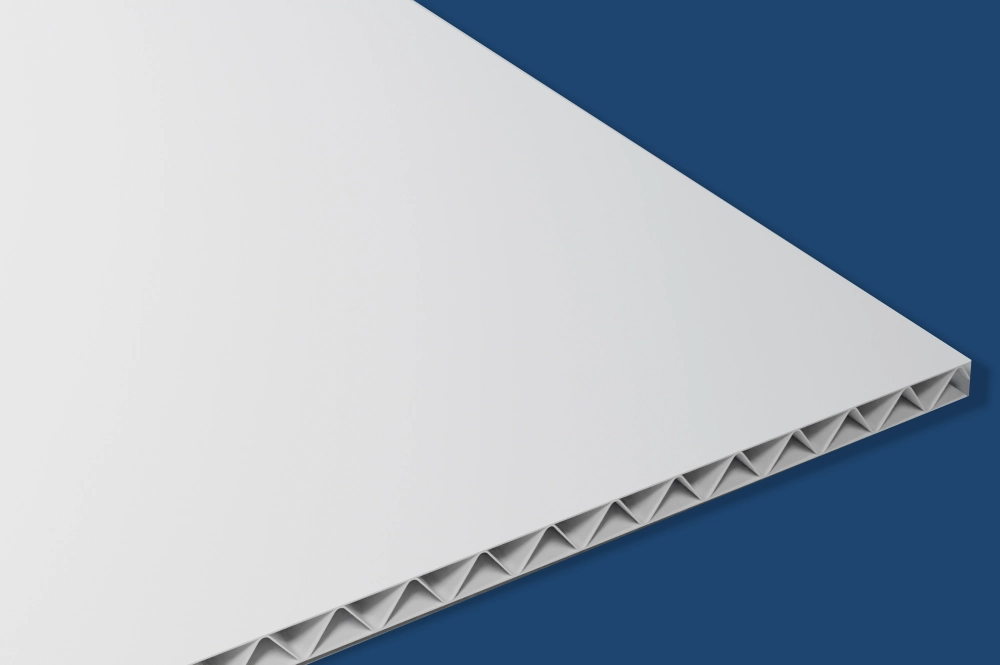

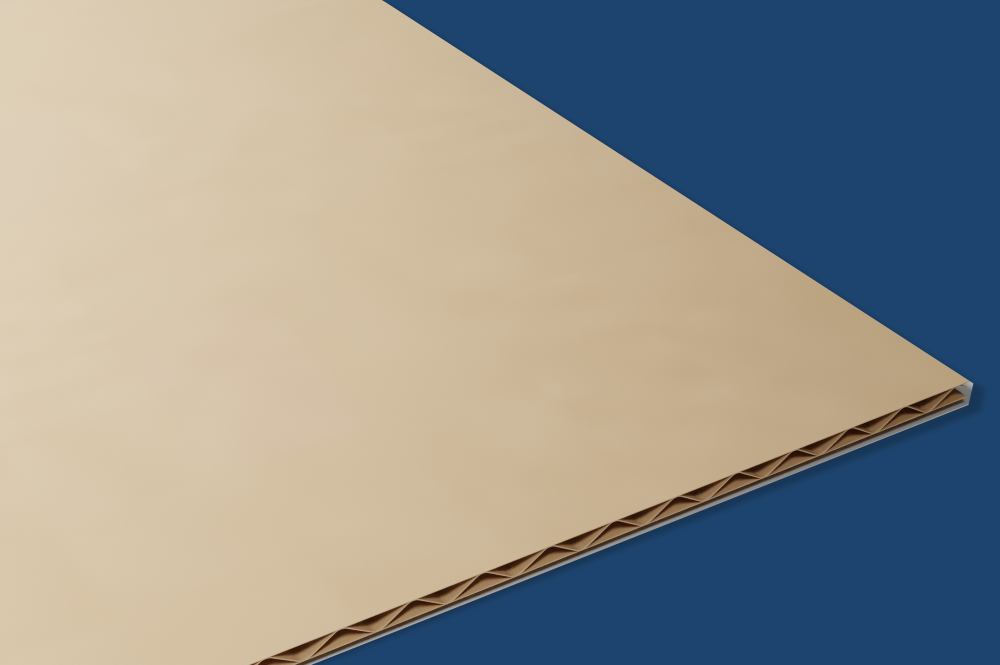

White flute

White flute

White linerboard with bleached white coating for high-quality printing and finishes.

E-flute

E-flute

A flat surface with a thickness level of 1/16" allows high-quality printing options.

B-flute

B-flute

A slightly thicker surface with a thickness level of 1/8" for die-cutting and high-quality printing.

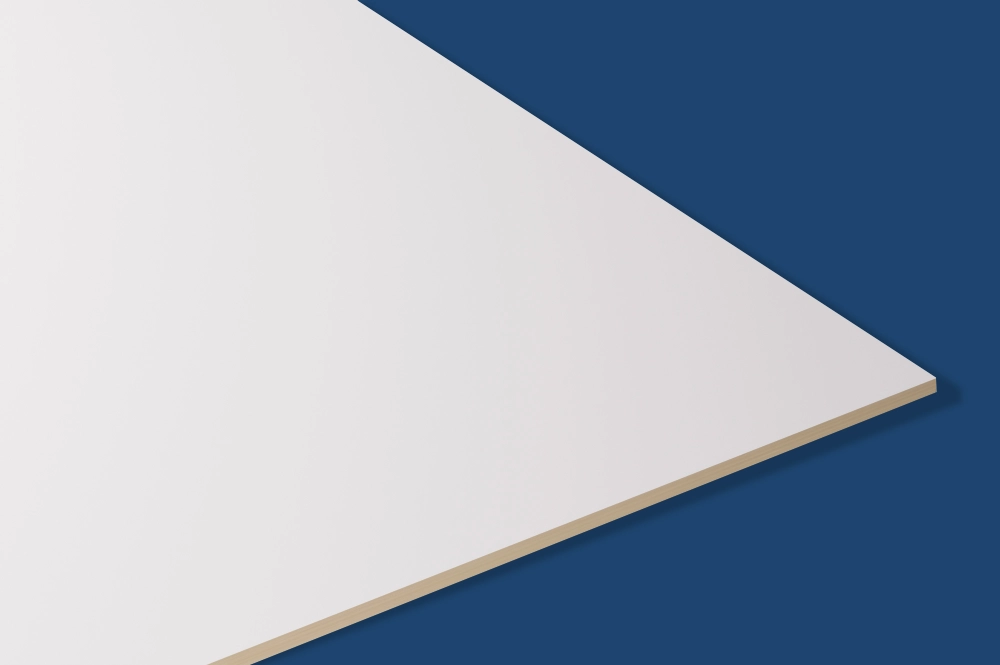

Grey Chipboard

Grey Chipboard

Grey Chipboard made of recyclable paper pulp, which is used in the construction of rigid boxes.

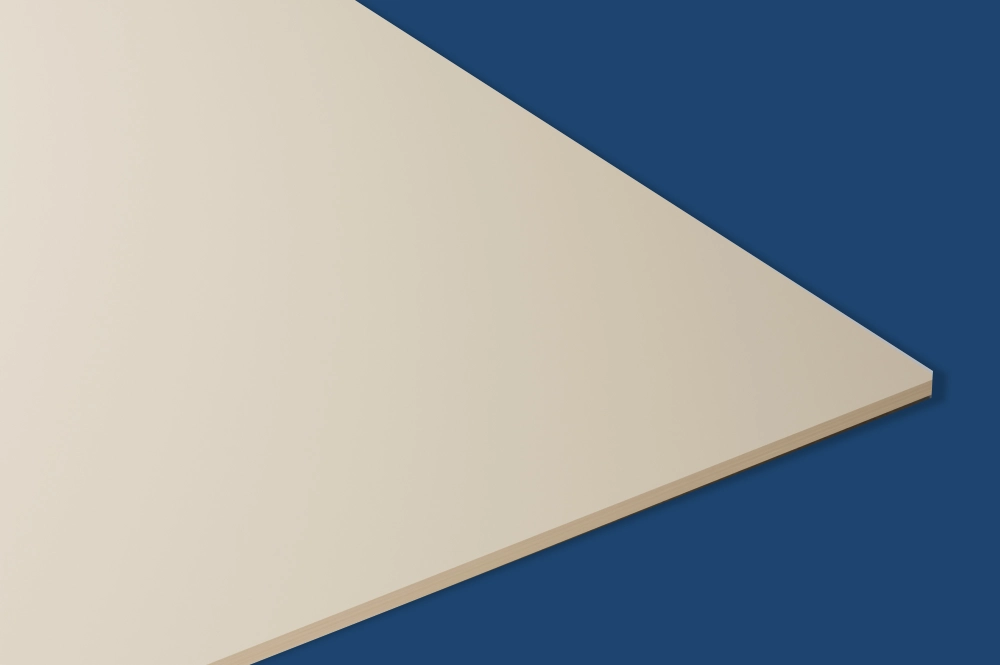

Duplex Chipboard

Duplex Chipboard

Duplex Chipboard made of recycled pulp paper with a white surface for high-quality printing.

Kraft Chipboard

Kraft Chipboard

Brown Kraft Chipboard is made of virgin and recycled pulp and coated on both sides for printing.

Aqueous

Aqueous

Water-based coating offers environmental friendliness and fast drying.

Gloss

Gloss

A highly reflective coating gives a shiny, polished appearance.

Matte

Matte

Diffused, non-reflective coating offering a subdued, elegant look.

Soft Touch

Soft Touch

This creates a velvety, tactile feel, often used for a luxurious effect.

UV Coating

UV Coating

Cured with ultraviolet light, provides instant drying, durable, and excellent chemical resistance.

Varnish

Varnish

Clear, hard coating that enhances protection and adds a glossy or matte finish.

Digital Print

Digital Print

A plate-less digital printing method where designs are transferred electronically. Cost-effective for short runs and quick turnaround.

Offset Print

Offset Print

High-quality printing method utilizing plates and a rubber blanket to transfer designs onto paper; ideal for large-volume production.

Screen Print

Screen Print

A printing method where ink is pushed through a mesh stencil onto a substrate. Ideal for bold graphics and thick ink deposits on diverse materials.

UV Print

UV Print

Fast-drying printing method using ultraviolet light to cure inks, resulting in a durable, glossy finish on various substrates.

CMYK

CMYK

A standard four-color printing process (Cyan, Magenta, Yellow, Black) is used to create a wide color spectrum.

Pantone

Pantone

A standardized color-matching system ensures accurate color reproduction across different printers and materials.

UV Ink

UV Ink

Instantly cured under UV light, it is ideal for printing on non-porous materials, with enhanced durability and vibrancy (can include metallic effects).

Soy Ink

Soy Ink

Eco-friendly ink alternative made from soybeans, offering brighter colors and improved biodegradability.

Blind UV

Blind UV

Creates a subtle, textured UV effect without added gloss.

Debossing

Debossing

Creates a depressed, indented effect on paper or cardstock.

Embossing

Embossing

Creates a raised, textured effect on paper or cardstock.

Foiling

Foiling

Adds a shiny, metallic finish to specific areas of a design.

Spot UV

Spot UV

Applies a glossy, clear coating to highlight specific areas of a design.

Window Patching

Window Patching

Incorporates a clear plastic window into packaging or print materials.

The term 'window' refers to a shape that has been die-cut from a folding carton and removed. The window patch is applied onto the folding cartons using a window patching machine, which applies adhesive inside the cartons within the perimeter of the window.

Folding boxes are flexible for printing and can have various finishes. They're often used in stores because they're affordable and can be customized in many ways.

We offer a whole range of folding carton box styles, including reverse tuck end, straight tuck end, auto Lock or auto Bottom Boxes, and many more. If you have a specific shape or box style in mind please let our design support know.

When choosing packaging materials, consider things like how heavy the product is, how it will be filled in the box, what it's used for, how long it will be on the shelf, what the store needs, how thick the paperboard is, and if it meets FDA and EPA regulations.

Yes. You can request a 3D mockup or 2D proof of your box from our design support team. Once you approve the digital proof, we will start the manufacturing process.

Looking to place a rush order? Get Your Order Shipped Fast! We accept rush orders on all of our products. Please fill out the form below and our chat support will contact you shortly.