Custom kraft boxes are eco-friendly packaging solutions made from natural kraft paperboard. They offer durability, a rustic appearance, and full customization for sustainable and retail-focused brands.

Get Free Quote

Custom kraft boxes are packaging boxes produced using kraft paperboard derived from natural wood pulp. These boxes are known for their brown, organic look that communicates sustainability and simplicity while still providing reliable product protection.

They are widely used by brands that prioritize eco-conscious packaging without compromising quality.

Kraft boxes combine strength with environmental responsibility. Key benefits include:

Made from recyclable and biodegradable materials

Strong fiber structure for durability

Natural appearance that appeals to eco-aware consumers

Suitable for printing and branding

These features make kraft boxes a popular choice for sustainable packaging.

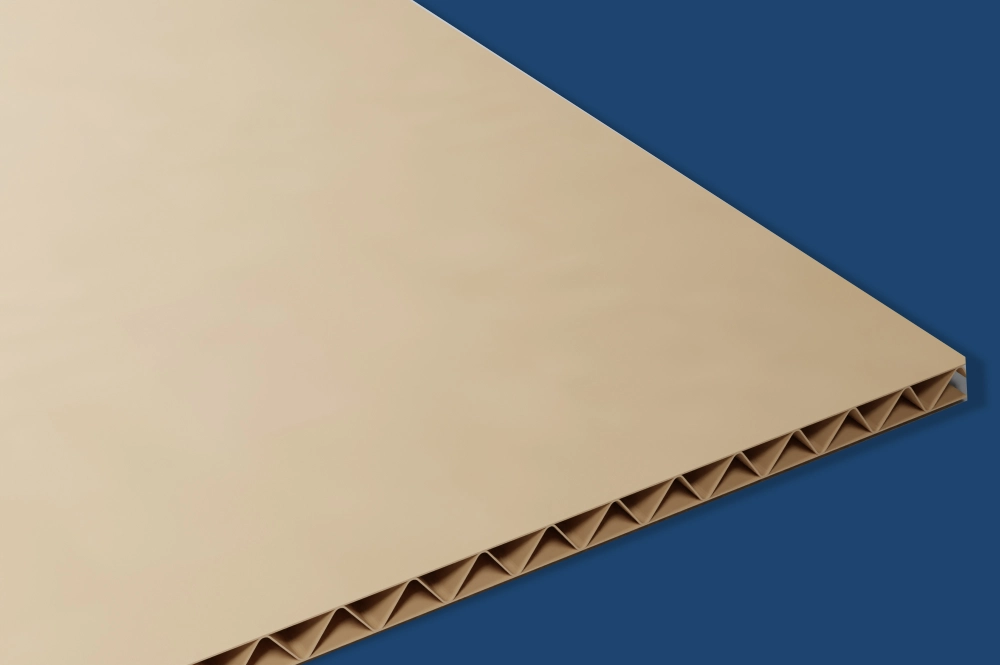

Custom kraft boxes are manufactured using different grades of kraft material, including:

Natural brown kraft paperboard

Bleached kraft for lighter color options

Corrugated kraft for shipping and protection

FSC-certified and recycled kraft materials

Material selection depends on product weight and packaging requirements.

Kraft boxes offer flexible customization while maintaining their natural look. Available options include:

One-color or full-color printing

Matte or aqueous coatings

Embossing, debossing, and foil stamping

Custom sizes and box styles

Die-cut windows and structural designs

Printing is optimized to complement the kraft texture.

These boxes are commonly used for:

Food and bakery packaging

Cosmetics and personal care products

Retail and e-commerce packaging

Subscription boxes and gift packaging

Handmade and artisan products

Their eco-friendly appeal enhances brand trust.

Custom kraft boxes help brands align with sustainability goals while delivering strong and attractive packaging. They reduce environmental impact, support branding, and offer dependable protection.

If you want packaging that is natural, durable, and environmentally responsible, custom kraft boxes are an excellent choice.

Choose a packaging style for your custom boxes, start designing with us, and get your boxes with the most advanced printing techniques.

Materials

Materials

Coating Options

Coating Options

Printing Methods

Printing Methods

Color Options

Color Options

AddOns

AddOns

SBS C1S

SBS C1S

Premium-grade bleached white paperboard with one-sided coating for high-quality color printing and finishes.

SBS C2S

SBS C2S

Premium-grade white art card coated on both sides for high-quality printing and finishing options.

Kraft Card

Kraft Card

Brown Kraft Card is made of virgin and recycled pulp and coated on both sides for printing.

Textured Card

Textured Card

Textured paper stock is primarily used to wrap rigid boxes and is of the highest grade.

Brown flute

Brown flute

An uncoated and unbleached linerboard composed of recycled and virgin paper pulp.

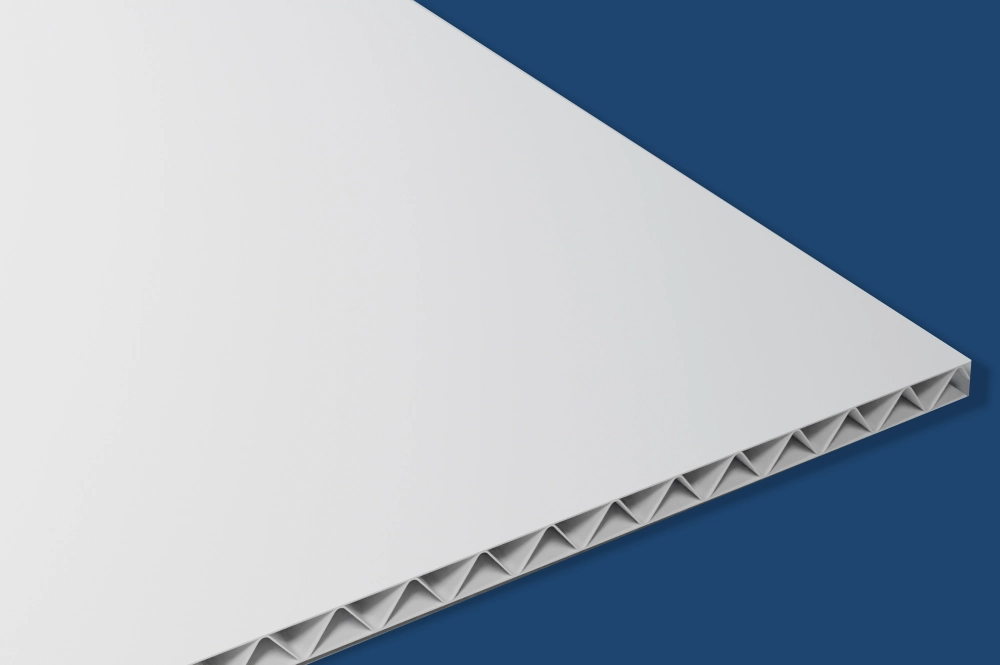

White flute

White flute

White linerboard with bleached white coating for high-quality printing and finishes.

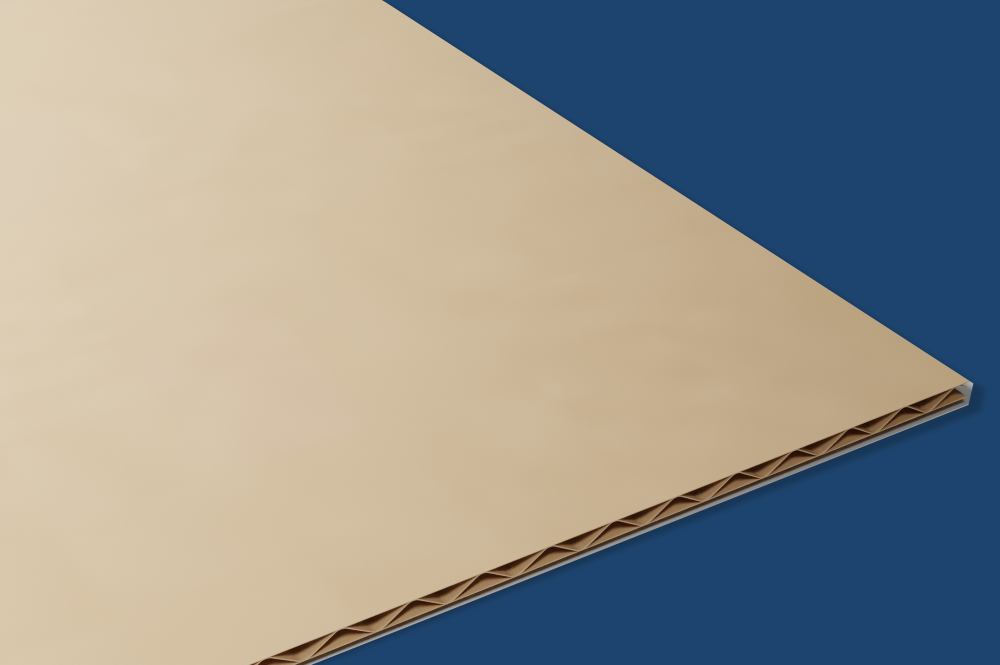

E-flute

E-flute

A flat surface with a thickness level of 1/16" allows high-quality printing options.

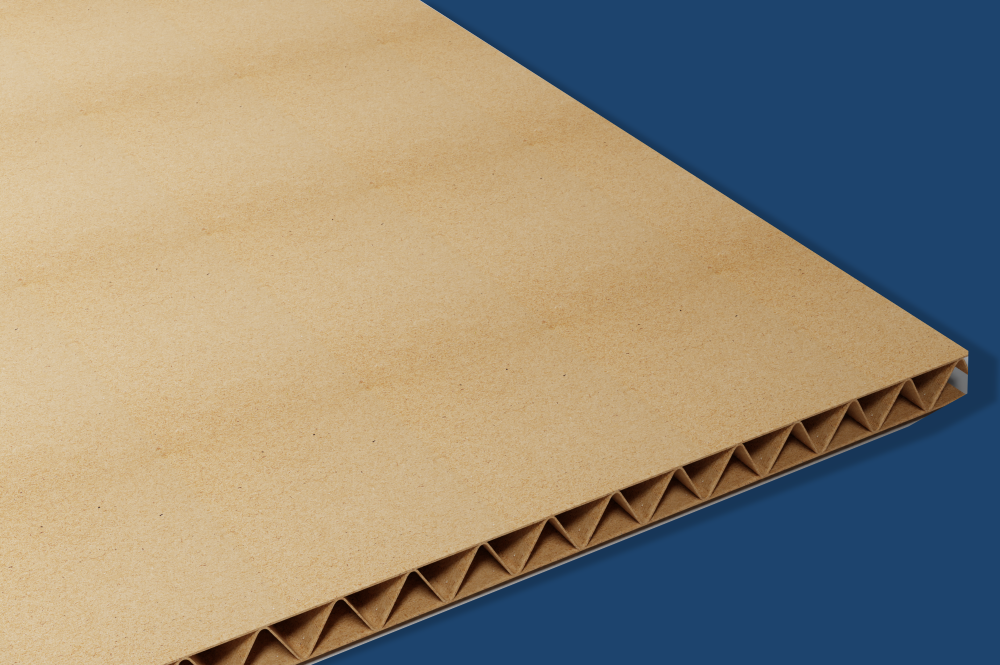

B-flute

B-flute

A slightly thicker surface with a thickness level of 1/8" for die-cutting and high-quality printing.

Grey Chipboard

Grey Chipboard

Grey Chipboard made of recyclable paper pulp, which is used in the construction of rigid boxes.

Duplex Chipboard

Duplex Chipboard

Duplex Chipboard made of recycled pulp paper with a white surface for high-quality printing.

Kraft Chipboard

Kraft Chipboard

Brown Kraft Chipboard is made of virgin and recycled pulp and coated on both sides for printing.

Aqueous

Aqueous

Water-based coating offers environmental friendliness and fast drying.

Gloss

Gloss

A highly reflective coating gives a shiny, polished appearance.

Matte

Matte

Diffused, non-reflective coating offering a subdued, elegant look.

Soft Touch

Soft Touch

This creates a velvety, tactile feel, often used for a luxurious effect.

UV Coating

UV Coating

Cured with ultraviolet light, provides instant drying, durable, and excellent chemical resistance.

Varnish

Varnish

Clear, hard coating that enhances protection and adds a glossy or matte finish.

Digital Print

Digital Print

A plate-less digital printing method where designs are transferred electronically. Cost-effective for short runs and quick turnaround.

Offset Print

Offset Print

High-quality printing method utilizing plates and a rubber blanket to transfer designs onto paper; ideal for large-volume production.

Screen Print

Screen Print

A printing method where ink is pushed through a mesh stencil onto a substrate. Ideal for bold graphics and thick ink deposits on diverse materials.

UV Print

UV Print

Fast-drying printing method using ultraviolet light to cure inks, resulting in a durable, glossy finish on various substrates.

CMYK

CMYK

A standard four-color printing process (Cyan, Magenta, Yellow, Black) is used to create a wide color spectrum.

Pantone

Pantone

A standardized color-matching system ensures accurate color reproduction across different printers and materials.

UV Ink

UV Ink

Instantly cured under UV light, it is ideal for printing on non-porous materials, with enhanced durability and vibrancy (can include metallic effects).

Soy Ink

Soy Ink

Eco-friendly ink alternative made from soybeans, offering brighter colors and improved biodegradability.

Blind UV

Blind UV

Creates a subtle, textured UV effect without added gloss.

Debossing

Debossing

Creates a depressed, indented effect on paper or cardstock.

Embossing

Embossing

Creates a raised, textured effect on paper or cardstock.

Foiling

Foiling

Adds a shiny, metallic finish to specific areas of a design.

Spot UV

Spot UV

Applies a glossy, clear coating to highlight specific areas of a design.

Window Patching

Window Patching

Incorporates a clear plastic window into packaging or print materials.

We believe custom packaging should be exceptional that’s why we’re passionate about creating boxes that leave a lasting impression. Our commitment to quality and customer satisfaction has earned us a loyal following. See for yourself:

“I was looking for a cosmetic box for lip gloss and i did not know which style to choose for my box. Refine Custom Boxes's agent Victor helped me to choose a reverse tuck end that was perfect for my product.”

“Overall a very positive experience! My boxes came out perfectly and the customer service was simply excellent.”

“My order was rushed, and they cooperated with me throughout the process, completing it within the given time. Excellent printing and material quality.”

If you don’t find what you are looking for, feel free to contact us via email and we will be happy to assist.

Yes. You will be assisted with the final file for review before we start manufacturing your order. Upon your approval, we will take your packaging to the production process.

You can customize all dimensions of your kraft box along with its style, shapes, and printing options.

The pricing of your box printing depends on multiple factors. Those factors may include the selection of material, its thickness level, finishing, and add-ons. Please fill in a quote form to get your instant quotation ready.

Yes. You have the option to ask for a 3D mock/2D proof for your artwork. Our design experts will send the 2D proof through mail. Upon your approval, we will proceed with the printing process.

Yes. You can request a 3D mockup or 2D proof of your box from our design support team. Once you approve the digital proof, we will start the manufacturing process.

Looking to place a rush order? Get Your Order Shipped Fast! We accept rush orders on all of our products. Please fill out the form below and our chat support will contact you shortly.