Custom sleeve boxes are two-piece packaging solutions consisting of an inner tray and an outer sleeve. They offer a sleek, modern presentation, secure product fit, and flexible customization for retail and premium packaging.

Custom sleeve boxes are packaging boxes made with an inner box or tray that slides into an outer sleeve. This design creates a smooth, layered unboxing experience while allowing ample space for branding on the sleeve.

They are widely used for products that require a clean look and controlled product reveal.

Sleeve boxes combine simplicity with elegance. Key structural benefits include:

Secure slide-in structure for product protection

Smooth opening experience for premium appeal

Extra branding space on the outer sleeve

Versatile design for various product sizes

This structure enhances both functionality and aesthetics.

Custom sleeve boxes can be manufactured using various materials depending on product weight and presentation needs, including:

Cardstock for lightweight retail packaging

Rigid paperboard for luxury sleeve boxes

Kraft paperboard for eco-friendly options

Recyclable and sustainable material options

Material selection depends on durability and brand positioning.

Sleeve boxes offer extensive customization to match brand identity. Available options include:

Full-color printing and custom artwork

Matte, gloss, or soft-touch lamination

Foil stamping, embossing, and spot UV

Custom sleeve widths and tray depths

Die-cut windows and inside printing

These boxes are commonly used for:

Cosmetics and beauty products

Electronics and accessories

Apparel and fashion items

Gift packaging and promotional products

Food and specialty retail items

Their minimal yet premium look suits modern brands.

Custom sleeve boxes provide a refined packaging solution that enhances unboxing while maintaining product security. They offer flexibility, visual appeal, and strong branding potential.

If you want packaging that feels modern, elegant, and functional, custom sleeve boxes are an excellent choice.

Choose a packaging style for your custom boxes, start designing with us, and get your boxes with the most advanced printing techniques.

Materials

Materials

Coating Options

Coating Options

Printing Methods

Printing Methods

Color Options

Color Options

AddOns

AddOns

SBS C1S

SBS C1S

Premium-grade bleached white paperboard with one-sided coating for high-quality color printing and finishes.

SBS C2S

SBS C2S

Premium-grade white art card coated on both sides for high-quality printing and finishing options.

Kraft Card

Kraft Card

Brown Kraft Card is made of virgin and recycled pulp and coated on both sides for printing.

Textured Card

Textured Card

Textured paper stock is primarily used to wrap rigid boxes and is of the highest grade.

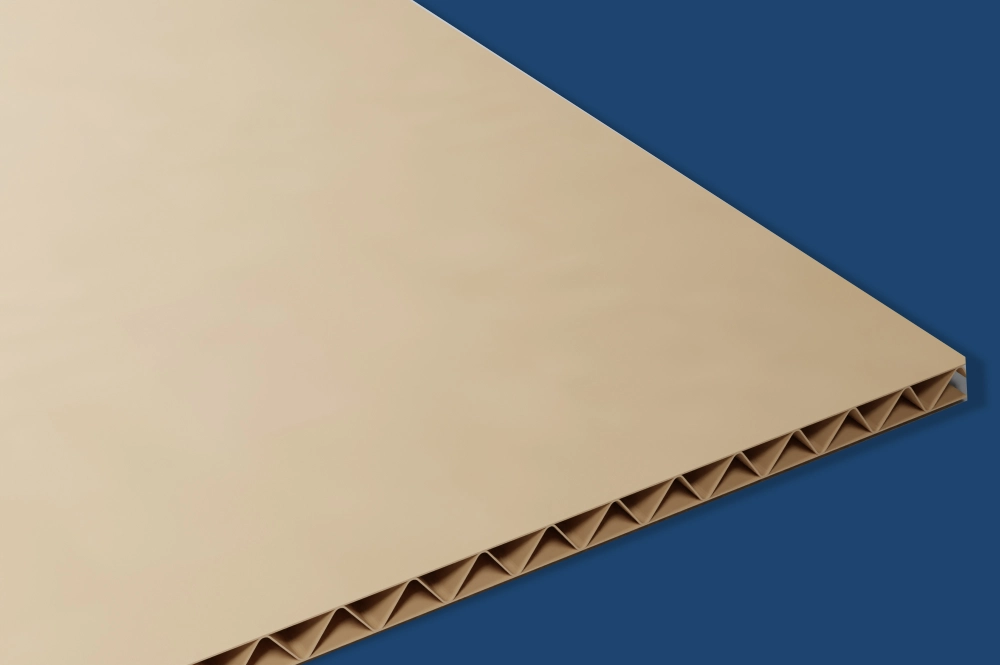

Brown flute

Brown flute

An uncoated and unbleached linerboard composed of recycled and virgin paper pulp.

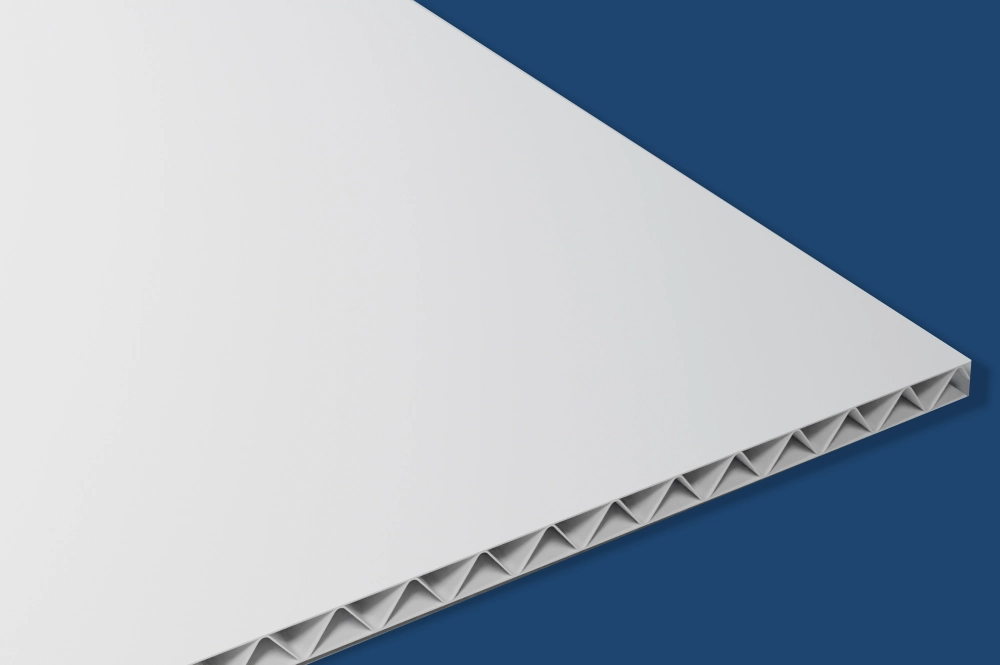

White flute

White flute

White linerboard with bleached white coating for high-quality printing and finishes.

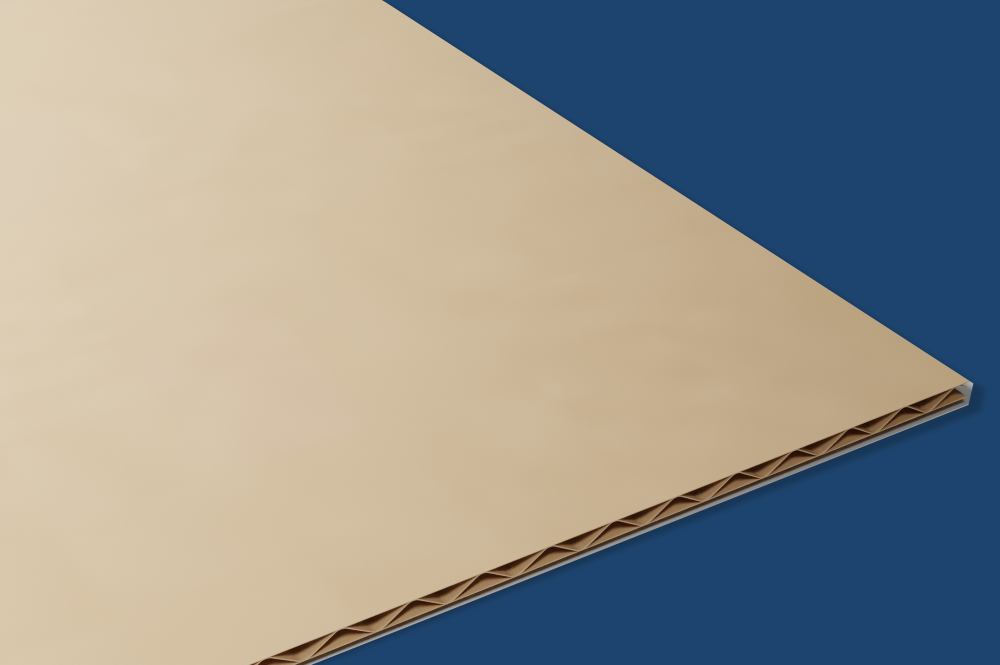

E-flute

E-flute

A flat surface with a thickness level of 1/16" allows high-quality printing options.

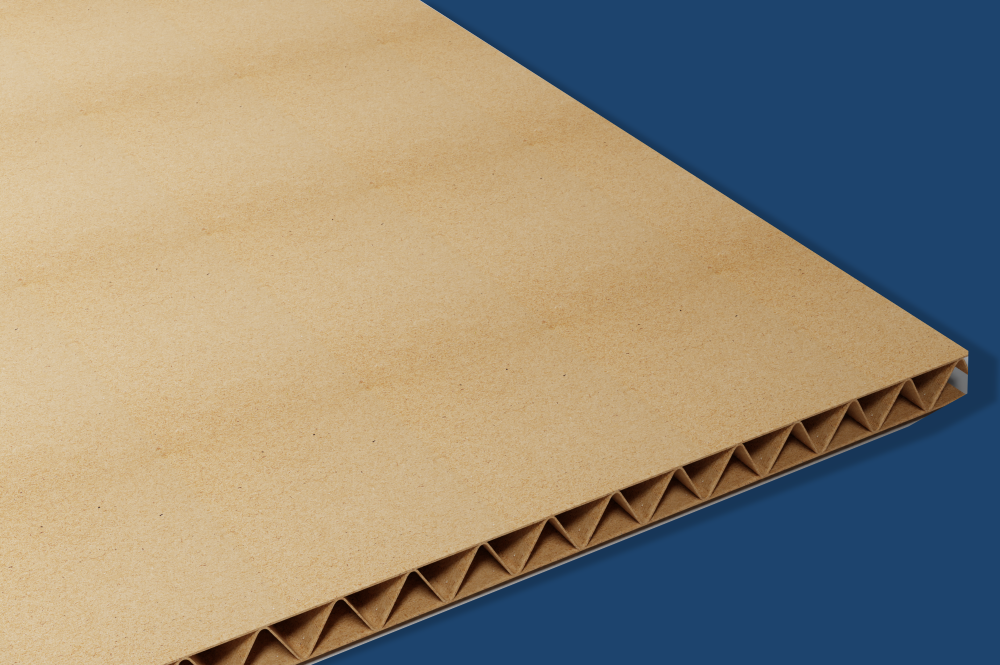

B-flute

B-flute

A slightly thicker surface with a thickness level of 1/8" for die-cutting and high-quality printing.

Grey Chipboard

Grey Chipboard

Grey Chipboard made of recyclable paper pulp, which is used in the construction of rigid boxes.

Duplex Chipboard

Duplex Chipboard

Duplex Chipboard made of recycled pulp paper with a white surface for high-quality printing.

Kraft Chipboard

Kraft Chipboard

Brown Kraft Chipboard is made of virgin and recycled pulp and coated on both sides for printing.

Aqueous

Aqueous

Water-based coating offers environmental friendliness and fast drying.

Gloss

Gloss

A highly reflective coating gives a shiny, polished appearance.

Matte

Matte

Diffused, non-reflective coating offering a subdued, elegant look.

Soft Touch

Soft Touch

This creates a velvety, tactile feel, often used for a luxurious effect.

UV Coating

UV Coating

Cured with ultraviolet light, provides instant drying, durable, and excellent chemical resistance.

Varnish

Varnish

Clear, hard coating that enhances protection and adds a glossy or matte finish.

Digital Print

Digital Print

A plate-less digital printing method where designs are transferred electronically. Cost-effective for short runs and quick turnaround.

Offset Print

Offset Print

High-quality printing method utilizing plates and a rubber blanket to transfer designs onto paper; ideal for large-volume production.

Screen Print

Screen Print

A printing method where ink is pushed through a mesh stencil onto a substrate. Ideal for bold graphics and thick ink deposits on diverse materials.

UV Print

UV Print

Fast-drying printing method using ultraviolet light to cure inks, resulting in a durable, glossy finish on various substrates.

CMYK

CMYK

A standard four-color printing process (Cyan, Magenta, Yellow, Black) is used to create a wide color spectrum.

Pantone

Pantone

A standardized color-matching system ensures accurate color reproduction across different printers and materials.

UV Ink

UV Ink

Instantly cured under UV light, it is ideal for printing on non-porous materials, with enhanced durability and vibrancy (can include metallic effects).

Soy Ink

Soy Ink

Eco-friendly ink alternative made from soybeans, offering brighter colors and improved biodegradability.

Blind UV

Blind UV

Creates a subtle, textured UV effect without added gloss.

Debossing

Debossing

Creates a depressed, indented effect on paper or cardstock.

Embossing

Embossing

Creates a raised, textured effect on paper or cardstock.

Foiling

Foiling

Adds a shiny, metallic finish to specific areas of a design.

Spot UV

Spot UV

Applies a glossy, clear coating to highlight specific areas of a design.

Window Patching

Window Patching

Incorporates a clear plastic window into packaging or print materials.

To measure your packaging sleeves, you'll need to determine the dimensions of your product and then measure the length, width, and height of the sleeve accordingly. Make sure to add some extra space for a snug fit, if necessary.

You can ask for a sample before ordering in bulk. Once you get satisfied with the final appearance and printing design of your box then order your required quantity. For further details, contact our custom support team for complete assistance.

Or we will provide you with the 3D mock-ups which will give you the clarity of how your custom box is going to look like. Once you are satisfied with the final appearance and printing design of your box then order your required quantity. For further details, contact our custom support team for complete assistance.

Yes, we provide our customers with dieline templates. These templates show the exact dimensions and layout of your packaging design, including where folds and cuts will be made. You can use these templates to ensure your artwork is correctly positioned and formatted.

You can submit your artwork in any of the following formats

Yes, absolutely! Mailer boxes are made of corrugated cardboard and come in two different thicknesses (E-flute 1/16" and B-flute 1/8") to suit your product type. Both options are perfect for shipping.

Yes. You can request a 3D mockup or 2D proof of your box from our design support team. Once you approve the digital proof, we will start the manufacturing process.

Looking to place a rush order? Get Your Order Shipped Fast! We accept rush orders on all of our products. Please fill out the form below and our chat support will contact you shortly.